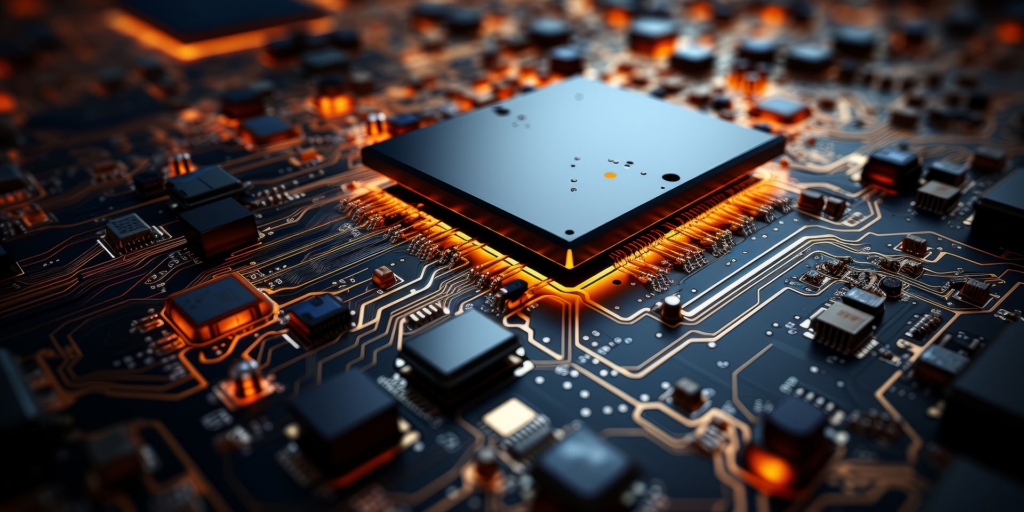

The electronics manufacturing landscape is shifting rapidly ⚡, with more clients demanding one-stop PCBA services that handle everything from PCB board fabrication 🏭 to circuit board assembly 🔌. Why? Let’s break down three key drivers behind this trend:

1. 💰 Transparent Pricing & Streamlined Procurement

With copper clad laminate 📉, PCB materials, and components like dual inline packages (DIP) 🌐 widely available online, pricing for PCB production and SMT process workflows has become highly competitive. However, fragmented sourcing—buying PCB circuits from one vendor and BGA chips from another—often leads to hidden costs 🕳️. One-stop PCBA manufacturers leverage bulk purchasing power for PCB components, lead-free solder 🌱, and 94V0 circuit boards, ensuring cost efficiency without compromising IPC Class standards ✅.

2. 🛠️ Rising Labor Costs & Supply Chain Risks

PCB assembly services now face pressure to reduce PCB costing 📊 amid unstable demand. Handling PCB fab and assembly in-house requires expertise in Altium Designer 🖥️ for design, KiCad software 🧩 for prototyping, and desoldering 🔄 techniques for rework—skills that drive labor expenses. Outsourcing to specialists minimizes risks like cold solder joints ❄️ or delays in multilayer circuit board deliveries 🚚, offering predictable budgets for PCB manufacturing processes.

3. 🔧 Technical Expertise Matters

PCBA manufacturers master niche details: optimal PCB stackups for high-frequency designs 📡, SMT line configurations for chip-on-board modules 🔍, or circuit board color choices 🌈 impacting thermal performance. They also navigate evolving standards like IPC Class 3 ✈️ for aerospace-grade PCB assembly or green circuit board finishes 🍃. Their expertise in PCB fabrication processes ensures reliability, whether producing dual-inline packages 📦 or managing vias in PCB chips 💻.

Social Media Teaser:

“🔧 Struggling with fragmented PCB production, SMT line delays, or BOM headaches? Discover why 72% of engineers now choose one-stop PCBA services for cost, quality, and faster turnaround! ⚡ [Read More]”

Call-to-Action:

Ready to simplify your workflow? 👉 Partner with EagleOpto for end-to-end PCBA manufacturing—from PCB design in Altium/KiCad to DIP package assembly. 🚀 [Get Your Free Quote Today!]